Disrupt Infrastructure – ‘Digital Twins’, the catalyst for real-world innovation.

In our latest contribution James Dean, CEO and Co-Founder, sensat, examines the extraordinary benefits using ‘digital twins’ for infrastructure development projects.

On a global scale, infrastructure plays an integral role in ensuring the function of modern society. Whether it’s the roads and railways that connect people to the resources they need or essential amenities like power plants and communications networks, infrastructure underpins all the technologies that enable modern living. This same infrastructure is just as essential to organisations which depend on power and instant communications for their business functions. However, with global growth increasing, there is a corresponding need for infrastructure to expand to accommodate increasing demand. Estimates suggest that $89 trillion in infrastructure investment is required by 2030 to maintain global growth. In light of this, it makes sense that infrastructure developers are finding and using the solutions that will enable this growth quickly, safely and at the lowest cost.

This is where digital solutions come in. Infrastructure is a predominantly physical industry – which means the sector has historically been slow to adopt digital transformation. As such, current methods of planning and delivering infrastructure are becoming increasingly outmoded as automation and artificial intelligence (AI) solutions become more viable for business operations and applicable to a wider range of use cases. In fact, offline industries not moving to integrate these solutions will result in an estimated $5.2 trillion direct economic loss per year. So what are these solutions?

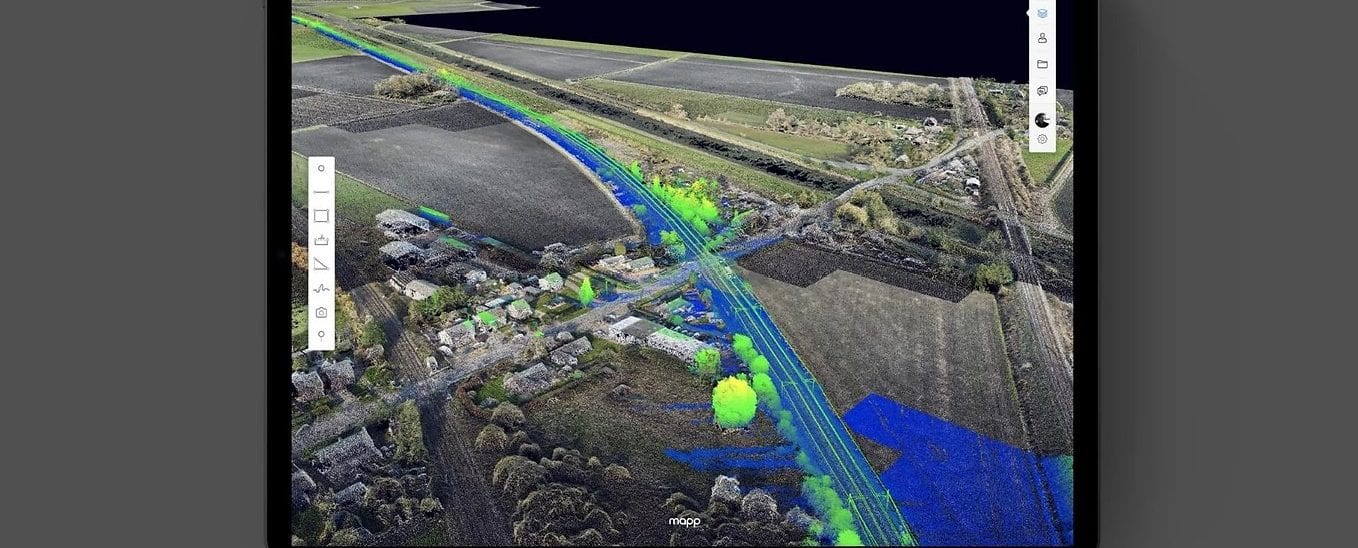

The first is ‘digital twins’ – digital replicas of real-world locations. Digital twins infuse real-time data from a wide set of sources to provide an accurate, digital model of what is occurring in a real-world location. This real-time data can be derived from a wide array of IoT devices to provide comprehensive data on everything from temperature, to foot-traffic to whether machines are in need of maintenance. Another advantage of digital twins is that they enable data capture 400x faster than traditional means, enabling projects to work on a greatly accelerated timeline. Since they depend on numerous data inputs, including drone or satellite imagery and Lidar, digital surveying allows for the mapping of areas that have traditionally been impossible or extremely time-consuming by other methods. Moreover, for challenging environments, such as those near large bodies of water or on difficult terrain, digital solutions eliminate the risk posed to human surveyors.

In themselves, these modern techniques are already a boon to the infrastructure development process. Not only is the greatly accelerated timeline drastically reducing costs, but the integration of digital tools is increasing safety. Where digital tools really create value, however, is in allowing the planning process to be kept in perfect sync with the real project. With a constant influx of real-time data, the planning process is constantly aligned with the actual state of construction. This allows for more accurate provision of resources and ensures that contractors are held accountable to the actual process on the site. Another consideration is that a unified view of the site prevents the risk of siloed working as conversations, calculations and analysis are less likely to be duplicated. Overall, digital tools allow for better decision-making as businesses have all the information they need at hand. These tools can be supported by AI-powered technologies that can easily compute these data-sets to create a comprehensive, real-time data-landscape. This reduces the burden for IT teams as AI does much of the heavy-lifting, allowing them to focus on value-on initiatives.

Already we are seeing modern infrastructure projects deploying some of these digital tools. They’re developing digital twins and using numerous sensors that produce continuous streams of data covering various stages of the construction process. The advantages of these processes should speak for themselves but as their capabilities develop and have more direct applications, it makes increasing operational sense to adopt. For the laggard organisations who don’t, significant losses in efficiency are likely.